Oerlikon Metco 8718 for Build-up Coating and Sealing D300 Spool Wire

Basic Info

Model No.: Oerlikon Metco 8718

Product Description

Model NO.: Oerlikon Metco 8718 Material: Oerlikon Metco 8718 PCD: Oerlikon Metco 8718 Hole: Oerlikon Metco 8718 Brand Name: Wisdom Surface: Bright Certificate: ISO9001 Resistance: Stable Application: Thermal Spray Coating Specification: ISO9001 HS Code: 75052200 Product Type: Wire Carbon Content: Low Carbon ET: Oerlikon Metco 8718 Place of Origin: Shanghai, China (Mainland) Model Number: Oerlikon Metco 8718 Melting Point: 1260°c-1340 °c Quality Test: Mill Test Report Dimensions: Customzied Trademark: WISDOM Origin: Shanghai, China Oerlikon Metco 8718 for build-up coating and sealing D300 spool wire

Introduction

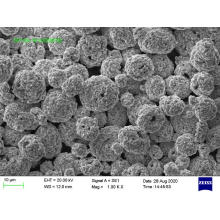

Oerlikon Metco 8718wire is a nickel super alloy frequently used for cryogenic storage tanks, turbines, down hole shafting and well head parts. High tolerance to extremely high and low temperatures allow inconel 718 to be welded and annealed into products that will withstand extreme conditions. Other uses include jet rocket, nuclear fuel, and pump body components.

It equivalent to: Alloy718, Tafa78T.

Surface Preparation

Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of preparation is, to grit blast with 24 mesh aluminum oxide, rough grind, or rough machine in a lathe.

Application

l Coating

l Casings

l Instrumentation components

l Nuclear fuel element spacers

l High-strength bolts

Chemical composition

Specifications

Physical Properties

Typical Deposit Characteristics

Standard Sizes & Packing

Other sizes can be produced by customers' requirement.

Contact us if you need more details on Thermal Spray Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Arc Spray Wire、Coating Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Introduction

Oerlikon Metco 8718wire is a nickel super alloy frequently used for cryogenic storage tanks, turbines, down hole shafting and well head parts. High tolerance to extremely high and low temperatures allow inconel 718 to be welded and annealed into products that will withstand extreme conditions. Other uses include jet rocket, nuclear fuel, and pump body components.

It equivalent to: Alloy718, Tafa78T.

Surface Preparation

Surface should be clean, white metal, with no oxides (rust), dirt, grease, or oil on the surface to be coated. Note: It is best not to handle surfaces after cleaning. Recommended method of preparation is, to grit blast with 24 mesh aluminum oxide, rough grind, or rough machine in a lathe.

Application

l Coating

l Casings

l Instrumentation components

l Nuclear fuel element spacers

l High-strength bolts

| Type | Composition(100%) | |||||||

| Ni | Cr | Fe | Others | Ti | Al | Co | ||

| Alloy 718 | 50-55 | 17-21 | Bal | 4.75-5.5 | 0.65-1.15 | 0.2-0.8 | Max 1.0 | |

| C | Mn | Si | P | S | Cu | B | ||

| Max 0.08 | Max 0.35 | Max 0.35 | Max 0.015 | Max 0.015 | Max 0.3 | Max 0.006 | ||

Specifications

| Grade | GE |

| Alloy 718 | B50TF202 |

| Grade | Density | Melting Point |

| Alloy 718 | 8.2g/cm3 | 1260°C-1340 °C |

| Typical Hardness | Bond Strength | Deposit Rate | Deposit Efficiency | Machilityineab |

| HRC 30 | 9000 psi | 10 lbs /hr/100A | 70% | Good |

| Diameter | Packing | Wire Weight |

| 1/16 (1.6mm) | D 300 Spool | 15kg(33 lb)/spool |

Contact us if you need more details on Thermal Spray Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Arc Spray Wire、Coating Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Thermal Spray Alloy

Premium Related Products

Other Products

Hot Products

B564 Alloy N10276 Corrosion Resistant Nickel Alloy (C-276)Uns S66286 (A-286) Stainless Material 660A/B/C/D for Fastener/Mould ProductsASTM Uns No6625 Saw Welding Wire Inconel 625High Quality Thermocouple Wire Type KHigh Quality High Temperature Alloy Nickel Wire Inconel 718 WiresCeramic TubeFlat Ribbon WireElectric Resistance StripHeat Resistant Electric Wire 0cr21al4 for Electric Heating ElementTop Quality Monel K500 WireConstantan Resistance Wire Copper Wire (CuNi1--CuNi44)Nickel Aluminum 95/5 Thermal Spray Coating WirePure Nickel Strip (Nickel 200/201)China Manufacturer Top-Quality Fecral Alloy BarNichrome Electric Resistance Alloy Wire (Cr20Ni35)Electric Resistance Wire of Fe-Cr-Al