Euqal to Tafa06c Wire for Build-up Coating and Sealing

Basic Info

Model No.: NiCr80/20 wire

Product Description

Model NO.: NiCr80/20 wire Material: Nicr PCD: Tafa06c Wire Hole: Nicr80/20 Wire Purity: High Purity 5n Color: Silver White Surface: Bright Brand: Wisdom Dimensions: 1.6mm Product Type: Wire Carbon Content: Low Carbon ET: -0.05mm Feature: Thermal Spray Wire with Standard: High Quality Tafa06c Wire for Arc Spray Wire Appearance: Wire Type: Tafa06c Thermal Spray Wire Name: Tafa06c Wire

Euqal to Tafa06C Wire for build-up coating and sealing

Nickel Chromium 80/20

Introduction

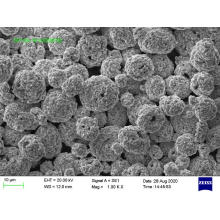

Nickel Chromium 80/20 wires are products appropriate for general use. The materials show an exothermic reaction during the spray process, Also produce coatings with high bond strengths that self-bond to most metallic substrates, Except the copper and tungsten based materials. It can equivalent to Tafa 06C

Nickel Chromium 80/20 widely used for electrical arc thermal spray application, It can produces dense,Well

bonded coatings with excellent machineability, electrical conductivity and high temperature oxidation resistance up to 1800 degrees F (980 degrees C). Widely applied to repair machine parts, electrical and high temperature corrosion applications.

Typical Uses and Applications

Bond Coatings under ceramic top coatings.

Build-up of machinable carbon steel and corrosion-resistant steels.

Under the condition of high temperature and low temperature as the Fretting resistance.

High-temperature anti-corrosive coating.

Chemical composition

Specifications

Physical Properties

Typical Deposit Characteristics

Standard Sizes & Packing

Other sizes (diameter and wire weight) can produced based on customers' requirement

Contact us if you need more details on Thermal Spray Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Arc Spray Wire、Coating Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Euqal to Tafa06C Wire for build-up coating and sealing

Nickel Chromium 80/20

Introduction

Nickel Chromium 80/20 wires are products appropriate for general use. The materials show an exothermic reaction during the spray process, Also produce coatings with high bond strengths that self-bond to most metallic substrates, Except the copper and tungsten based materials. It can equivalent to Tafa 06C

Nickel Chromium 80/20 widely used for electrical arc thermal spray application, It can produces dense,Well

bonded coatings with excellent machineability, electrical conductivity and high temperature oxidation resistance up to 1800 degrees F (980 degrees C). Widely applied to repair machine parts, electrical and high temperature corrosion applications.

Typical Uses and Applications

Bond Coatings under ceramic top coatings.

Build-up of machinable carbon steel and corrosion-resistant steels.

Under the condition of high temperature and low temperature as the Fretting resistance.

High-temperature anti-corrosive coating.

Chemical composition

| Nominal composition | Cr % | Ni % |

| Min | 20.0 | |

| Max | Bal. |

Specifications

| Grade | GE | PWA |

| Nickel Chrome 80/20 | B50TF119 | 36947 |

Physical Properties

| Grade | Density | Melting point °C | Electrical resistivity at 20°C Ω mm2/m |

| Nickel Chrome 80/20 | 8.3g/cm3 | 1400 | 1.09 |

Typical Deposit Characteristics

| Typical Hardness | Bond Strength | Deposit Rate | Deposit Efficiency | Machilityineab |

| HRB 90 | 7300 psi | 11 lbs/hr/100A | 65-75 % | Good |

Standard Sizes & Packing

| Diameter | Dimension tolerance (mm) | Packing | Wire Weight |

| 1/16 (1.6mm) | + 0/-0.05 | D 300 Spool | 15kg/spool |

Other sizes (diameter and wire weight) can produced based on customers' requirement

Contact us if you need more details on Thermal Spray Wire. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Arc Spray Wire、Coating Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Thermal Spray Alloy

Premium Related Products

Other Products

Hot Products

B564 Alloy N10276 Corrosion Resistant Nickel Alloy (C-276)Uns S66286 (A-286) Stainless Material 660A/B/C/D for Fastener/Mould ProductsASTM Uns No6625 Saw Welding Wire Inconel 625High Quality Thermocouple Wire Type KHigh Quality High Temperature Alloy Nickel Wire Inconel 718 WiresCeramic TubeFlat Ribbon WireElectric Resistance StripHeat Resistant Electric Wire 0cr21al4 for Electric Heating ElementTop Quality Monel K500 WireConstantan Resistance Wire Copper Wire (CuNi1--CuNi44)Nickel Aluminum 95/5 Thermal Spray Coating WirePure Nickel Strip (Nickel 200/201)China Manufacturer Top-Quality Fecral Alloy BarNichrome Electric Resistance Alloy Wire (Cr20Ni35)Electric Resistance Wire of Fe-Cr-Al