ISO 9001 Certificate Stellite 21 Welding Rod

Basic Info

Model No.: Stellite 21

Product Description

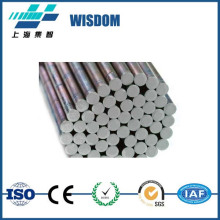

Model NO.: Stellite 21 Material: Cobalt Based Length: 300-400mm Electrode Coating Type: Base Stainless Steel Welding Rod Type: Cobalt Welding Welding Power: DC Application: Hardfacing Welding MOQ: 5kg for Stellite 21 Payment Currency: USD/Eur/RMB Process: Continuous Casting Trademark: WISDOM Origin: Shanghai, China Type: Cobalt Welding Electrodes Diameter: 3.2mm Welding Core Type: Alloy Structural Steel Slag Characteristic: Alkaline Function: Hardfacing Electrode Certificate: ISO 9001 Delivery Time: 5-20days of Stellite 21 Quality Test: Mill Test Report Brand Name: Wisdom Product: Stellite 21 Specification: ISO 9001 ISO 9001 certificate Stellite 21 welding rod WISDOM Brand Chinese Leading Manufacturer Hardfacing welding series PRODUCT INTRODUCTION WISDOM Stellite's™ cobalt base alloys are available as cobalt rods, cobalt electrodes, cobalt wire and cobalt powder. Cobalt alloys are used primarily for wear applications, our cobalt alloys can be applied by any known fusion welding process or HVOF spraying proess and are particularly well-suited for hardfacing applications. Cobalt alloys are the most widely used wear resistant hardfacing materials available. Their unique combination of wear resistance, strength and corrosion resistance make them adaptable to many harsh environments. Cobalt alloys are selected for their excellent resistance to the widest combination of wear types including adhesive wear, abrasion, erosion, contact fatigue, thermal shock, cavitation wear, corrosion and oxidation. The degree to which the cobalt alloys retain these properties assures their unique position in the wear technology field.

AWS RCoCr-C (Stellite 1)

It has excellent wear and heat resistance at high temperature.

Recommended use for making valve seal inserts , rotating sealing ring, drill heads, cutter edge ,etc AWS RCoCr-A (Stellite 6)

The most widely used Cobalt Alloy with good mechanical

properties at different temperatures, Recommended use

for making valve seat material, hot shear blade, high temperature valve , turbine blade ,etc. AWS RCoCr-B (Stellite 12)

It has excellent resistance on high heat, corrosion

and abrasion. Recommended use for making high-

pressure valve, shear edge, sawteeth, etc. AWS RCoCr-B (Stellite 21) It has excellent resistance on high heat, corrosion

and abrasion. Recommended use for making fuild valve, brass casting die , vlave seat, etc. Features: 1) Powder of three main alloys: cobalt-base alloy, nickel-base alloy, and

iron-base alloy, stellite alloy

2) Properties: good resistance against high-temperature, corrosion, wear,

shock and stick abrasion

3) Main application: use to repair and pre-protection of valve seat, pump

shaft sleeve and valve gate

4) Process: OXY, PTA, high frequency remelting

5) Specifications: 150/320, 200/400, 280/400, 180/400, 60/170, 60/200 PACKING DETAILS About Delivery and shipping 1. For the products which we have raw material in stock. We can deliver the products within 7-10 days after the payment has been confirmed. We will choose the shipping way as you required: By sea, by air, by express, etc. As for the costs and shipping period information, please contact us via telephone, mail or online trade manager. 2.For the products need to start from smelting We will finish the production within 20-25 days after the deposit has been confirmed. We will choose the shipping way as you required: By sea, by air, by express, etc. As for the costs and shipping period information, please contact us via telephone, mail or online trade manager. Contact us if you need more details on Stellite 21. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stellite 21 Rod、Stellite 21 Welding Rod. If these products fail to match your need, please contact us and we would like to provide relevant information.

ALLOY | NOMINAL ANALYSIS OF BARE ROD |

| Hardness (HRC) | |||||||

| Co | Cr | W | C | Ni | Mo | Fe | Si | Others |

|

COBALT BASE ALLOY BARE RODS | ||||||||||

Stellite 1 | Bal. | 30 | 13 | 2.45 | <3.0 | <1.0 | <3.0 | <1.0 | <0.5 | 50-58 |

Stellite 6 | Bal. | 29 | 4 -5 | 1.2 | <3.0 | <1.0 | <3.0 | <2.0 | <0.5 | 40-46 |

Stellite 12 | Bal. | 30 | 8.5 | 1.4-1.8 | <3.0 | <1.0 | <3.0 | <2.0 | <0.5 | 44-50 |

Stellite 21 | Bal. | 27 | 0.20 | 0.25 | 3 | 5.2 | <3.0 | <1.5 | <0.5 | 20 |

It has excellent wear and heat resistance at high temperature.

Recommended use for making valve seal inserts , rotating sealing ring, drill heads, cutter edge ,etc AWS RCoCr-A (Stellite 6)

The most widely used Cobalt Alloy with good mechanical

properties at different temperatures, Recommended use

for making valve seat material, hot shear blade, high temperature valve , turbine blade ,etc. AWS RCoCr-B (Stellite 12)

It has excellent resistance on high heat, corrosion

and abrasion. Recommended use for making high-

pressure valve, shear edge, sawteeth, etc. AWS RCoCr-B (Stellite 21) It has excellent resistance on high heat, corrosion

and abrasion. Recommended use for making fuild valve, brass casting die , vlave seat, etc. Features: 1) Powder of three main alloys: cobalt-base alloy, nickel-base alloy, and

iron-base alloy, stellite alloy

2) Properties: good resistance against high-temperature, corrosion, wear,

shock and stick abrasion

3) Main application: use to repair and pre-protection of valve seat, pump

shaft sleeve and valve gate

4) Process: OXY, PTA, high frequency remelting

5) Specifications: 150/320, 200/400, 280/400, 180/400, 60/170, 60/200 PACKING DETAILS About Delivery and shipping 1. For the products which we have raw material in stock. We can deliver the products within 7-10 days after the payment has been confirmed. We will choose the shipping way as you required: By sea, by air, by express, etc. As for the costs and shipping period information, please contact us via telephone, mail or online trade manager. 2.For the products need to start from smelting We will finish the production within 20-25 days after the deposit has been confirmed. We will choose the shipping way as you required: By sea, by air, by express, etc. As for the costs and shipping period information, please contact us via telephone, mail or online trade manager. Contact us if you need more details on Stellite 21. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stellite 21 Rod、Stellite 21 Welding Rod. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Welding Material > Welding Bare Rods

Premium Related Products

Other Products

Hot Products

B564 Alloy N10276 Corrosion Resistant Nickel Alloy (C-276)Uns S66286 (A-286) Stainless Material 660A/B/C/D for Fastener/Mould ProductsASTM Uns No6625 Saw Welding Wire Inconel 625High Quality Thermocouple Wire Type KHigh Quality High Temperature Alloy Nickel Wire Inconel 718 WiresCeramic TubeFlat Ribbon WireElectric Resistance StripHeat Resistant Electric Wire 0cr21al4 for Electric Heating ElementTop Quality Monel K500 WireConstantan Resistance Wire Copper Wire (CuNi1--CuNi44)Nickel Aluminum 95/5 Thermal Spray Coating WirePure Nickel Strip (Nickel 200/201)China Manufacturer Top-Quality Fecral Alloy BarNichrome Electric Resistance Alloy Wire (Cr20Ni35)Electric Resistance Wire of Fe-Cr-Al